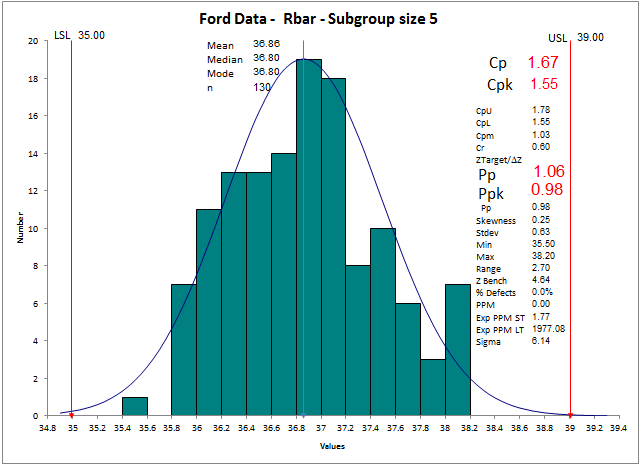

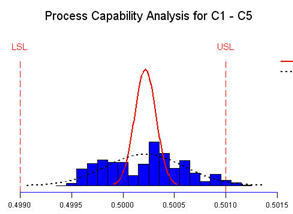

Then verify again the normality using a normality test. Use the Box-Cox transformation to improve the normality of the data set. If the data are not normally distributed, you have the following possibilities to obtain results for the process capabilities. By the use of a normality test, you can verify these premises (see the Normality Tests in XLSTAT-Base). Note: During the interpretation of the different indicators for the process capability please pay attention to the fact that some indicators suppose normality or at least symmetry of the distribution of the measured values. If the distributions of the measured variables are in the technical specification limits, then the process is called "capable". Process capability describes a process and informs if the process is under control and the distribution of the measured variables are inside the specification limits of the process. Ŝ = s / c4, where c4 is the control chart constant according to Burr (1969). standard deviation: The estimator for sigma is calculated based on the standard deviation of the n measurements.Ŝ = median / d4, where d4 is the control chart constant according to Burr (1969). Median moving range: The estimator for sigma is calculated based on the median of the moving range using a window length of m measurements.Ŝ = m / d2, where d2 is the control chart constant according to Burr (1969). Average moving range: The estimator for sigma is calculated based on the average moving range using a window length of m measurements.XLSTAT Individual charts option offers you the following options for the estimation of the standard deviation (sigma) of the data set, given n measurements: Note 3: If you have measurements in qualitative values (for instance ok, not ok, conform not conform), then use the control charts for attributes. Note 2: If you have more than one measurement for each point in time, then you should use the control charts for subgroups. Note 1: If you want to investigate smaller mean shifts, then you can also use CUSUM individual charts which are often preferred in comparison with the individual control charts, because they can detect smaller mean shifts. Large difference in production, caused by the use of different production lines, will be easily visible. MR moving range: An MR chart (moving range diagram) is useful to analyze the variability of the production.Mean shifts are easily visible in the diagrams. X Individual: An X individual chart is useful to follow the moving average of a production process.The individual charts tool offers you the following chart types alone or in combination: In the following lines, we use the wording from the production and shop floors. Today this approach is being applied to a large number of different fields, for instance services, human resources, and sales.

Therefore the wording is still from that domain. With the development of CUSUM, UWMA and EWMA charts in 1936, Deming expanded the set of available control charts.Ĭontrol charts were originally used in area of goods production. He described his methods completely in his book (1931).įor a long time, there was no significant innovation in the area of control charts. Control charts were first mentioned in a document by Walter Shewhart that he wrote during his time working at Bell Labs in 1924. Individual charts are a type of control chart used to monitor the processes in statistical process control (SPC).

0 kommentar(er)

0 kommentar(er)